The Printed Circuit Board (PCB) is the backbone of modern electronics, enabling devices from smartphones to industrial machinery to function seamlessly. At Jinxinyang, accessible at https://www.pcbinq.com/, we specialize in delivering high-quality PCB design, manufacturing, and assembly services, with a focus on material customization to meet diverse industry needs. Our expertise in selecting the right materials, such as FR4, Polyimide, Rogers, and Aluminum, ensures optimal performance, durability, and thermal management. Additionally, tools like the SMD Resistor Code Calculator help engineers streamline PCB design by decoding resistor values accurately. This article explores Jinxinyang’s PCB offerings and material customization services.

The Role of PCBs in Electronics

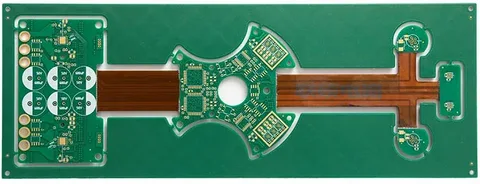

A Printed Circuit Board connects electronic components through conductive copper pathways etched onto a non-conductive substrate, such as fiberglass or epoxy. The choice of materials, copper thickness, and features like epoxy-filled vias significantly impact the board’s performance, strength, and thermal efficiency. Jinxinyang offers a wide range of PCB types, including Single-Sided PCB, Double-Sided PCB, Multilayer PCB, Rigid PCB, Flexible PCB, Rigid-Flex PCB, Standard PCB, HDI PCB, and High-Frequency PCB, each tailored to specific applications.

Jinxinyang’s PCB Types and Applications

- Single-Sided PCB: Featuring conductive traces on one side, these cost-effective boards are ideal for simple applications like LED lighting and sensors.

- Double-Sided PCB: With conductive layers on both sides, these boards support complex circuits for automotive and industrial applications.

- Multilayer PCB: These boards enable intricate designs for high-performance devices like smartphones and medical equipment.

- Rigid PCB: Built for durability, rigid boards are used in computers and industrial machinery.

- Flexible PCB: Made from flexible materials like polyimide, these boards are perfect for wearables and medical implants.

- Rigid-Flex PCB: Combining rigid and flexible designs, these boards are ideal for aerospace and military applications.

- Standard PCB: Adhering to industry standards, these boards are versatile for general-purpose devices.

- HDI PCB: High-density interconnect boards optimize space for compact devices like tablets.

- High-Frequency PCB: Designed for low signal loss, these boards support telecommunications and 5G infrastructure.

Material Customization for Optimal Performance

Jinxinyang’s professional services focus on material customization to meet specific customer needs. The choice of material affects how a PCB board performs, its strength, and its ability to handle heat.

- Copper Thickness: Copper forms the conductive paths in a PCB circuit. Thicker copper, such as 30 ounces or more, enhances current-carrying capacity, making it ideal for high-power designs like power supplies. Jinxinyang customizes copper thickness to ensure efficient current flow and reliability.

- Epoxy Filled Vias: For boards requiring a flat surface or added strength, Jinxinyang uses epoxy-filled vias to protect against air, water, and thermal stress, enhancing durability in high-pressure environments.

- FR4: The most common PCB material, FR4 combines fiberglass and epoxy for strength and affordability, suitable for a wide range of applications.

- Polyimide: Ideal for high-heat environments, polyimide offers flexibility and durability, making it perfect for Flexible PCBs in harsh conditions.

- Rogers: Designed for high-frequency applications, Rogers materials minimize signal loss, making them a top choice for RF designs and 5G infrastructure.

- Aluminum: With its metal base, aluminum excels in heat dissipation, making it ideal for LED lighting and power tools where thermal management is critical.

Streamlining Design with the SMD Resistor Code Calculator

Accurate component selection is vital in PCB design. Jinxinyang provides tools like the SMD Resistor Code Calculator to help engineers decode surface-mount resistor values quickly, ensuring precise integration into PCB circuits. This tool simplifies the design process, reducing errors and saving time, especially for complex boards like HDI PCBs and High-Frequency PCBs.

Jinxinyang’s Manufacturing and Assembly Excellence

Jinxinyang’s state-of-the-art facilities use advanced techniques like laser drilling and automated optical inspection to produce high-quality circuit PCB boards. Our PCB assembly process employs surface-mount technology (SMT) and through-hole technology, ensuring precision and reliability for boards like Multilayer PCBs and Flexible PCBs. Rigorous quality control guarantees that every board meets industry standards.

Driving Innovation and Sustainability

Jinxinyang is committed to innovation, supporting emerging technologies like IoT, 5G, and autonomous vehicles with High-Frequency PCBs and HDI PCBs. We also prioritize sustainability, using eco-friendly materials and lead-free soldering to minimize environmental impact. Our exploration of 3D-printed PCBs enables rapid prototyping for custom projects.

Conclusion

Jinxinyang leads the industry in delivering customized circuit PCB boards, leveraging material expertise and tools like the SMD Resistor Code Calculator to drive innovation. Visit https://www.pcbinq.com/ to explore how our PCB design and PCB assembly services can power your next project.