A welder in Alabama might tell you—there’s a big difference between pulling a trigger and programming a cut. In a world where precision and speed shape the success of metal fabrication, understanding how tools work makes all the difference. That’s especially true for choosing between a regular plasma cutter and a CNC plasma cutter in Alabama.

Manual Operation vs. Computer-Controlled Production Efficiency

A standard plasma cutter gives the operator full control. You guide the torch by hand, tracing lines across sheet metal with skill and experience. That makes it ideal for jobs that require quick, straightforward cuts without programming. It’s a practical choice in small shops or field work where setup time needs to be minimal, and projects vary from day to day.

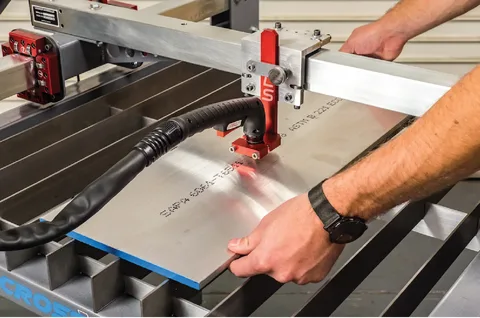

Now compare that to a CNC plasma cutter in Alabama, which trades hand movement for computer commands. It takes uploaded design files and executes cuts with extreme accuracy—over and over again. This shift to automated control improves production speed, reduces human error, and keeps operations running efficiently, especially in environments where deadlines and repeat orders dominate.

Fabrication Versatility vs. Uniform Repeatability

Regular plasma cutters offer a kind of freedom. They’re easy to move around, adapt well to odd jobs, and allow fabricators to respond on the fly. This makes them a favorite in repair shops and mobile welding services, where no two projects look the same. The tool becomes an extension of the welder’s hand—every arc and angle unique.

CNC systems bring repeatability into the mix. Once the digital blueprint is set, it’s possible to cut identical pieces across multiple sheets, batches, or days—without deviation. That level of precision is essential for robotics engineering companies in Alabama building machines that need perfectly matching parts. It’s less about improvisation and more about control.

Operator Skill Reliance vs. Software-Driven Performance

A hand-held plasma cutter rewards experience. The quality of each cut often depends on how steady the operator’s hand is, how well they measure, and how they adjust to material thickness and shape. It takes years to get great at it, and even then, results can vary slightly from one job to the next.

With CNC plasma systems, the software does the heavy lifting. Operators still need to understand machine setup and material behavior, but precision cutting is handled through G-code files and CAD designs. The machine doesn’t fatigue or lose focus, making it a powerful tool for teams that want high-quality output with less dependency on expert-level cutting skills.

Basic Metal Cutting Applications vs. Complex Fabrication Tasks

In many shops across Alabama, standard plasma cutters tackle tasks like slicing brackets, trimming pipe, or cutting steel panels to size. These jobs don’t demand intricate patterns or tiny tolerances. They’re the bread-and-butter tasks of metalwork—fast, functional, and hands-on.

But things change when the work calls for ornate metal signage, robotic assemblies, or parts for automation systems. A CNC plasma cutter in Alabama handles those complex shapes with ease, cutting detailed designs straight from a digital file. Intricate holes, custom geometries, and symmetrical parts become simple tasks, opening new doors for robotics and industrial fabrication.

Hands-On Adjustment vs. Digitally Programmed Consistency

A traditional plasma cutter requires constant operator feedback. If the material is thicker than expected or the cut starts to drift, adjustments happen in real time—changing angles, pausing the cut, or tweaking speed on the fly. It’s an art form in a way, and it keeps the user fully engaged from start to finish.

CNC machines change that rhythm. Once the settings are locked in and the file is loaded, the machine follows it to the letter. That level of digital consistency means cuts are uniform every time. No guessing, no mid-process tweaking. For any robotics engineering company in Alabama producing repeat components, this reliability is a game changer.

Workshop Simplicity vs. Industrial-Grade Integration

Manual plasma cutters fit easily into most metal shops. They need a power source, compressed air, and a steady hand. Their setup is simple, and so is their maintenance. They’re mobile and can be stored when not in use—great for operations that value flexibility.

On the other end, CNC plasma cutters are more involved. These machines often integrate with broader production lines and rely on supporting software, fume extraction systems, and tables for handling larger materials. They’re built to handle heavy-duty workflows, and while the investment is greater, so is the potential for high-end fabrication.

Short-Run Flexibility vs. High-Volume Production Capability

Short-run projects benefit from the adaptability of a hand-held plasma cutter. If a shop in Alabama needs to fabricate a few custom brackets or make fast modifications, the setup is nearly instant. The operator can pivot between tasks, make creative adjustments, and finish jobs quickly without the overhead of digital prep.

But for high-volume manufacturing, CNC plasma cutters shine. Whether it’s cutting hundreds of parts for automated systems or churning out metal panels for robotic arms, the machine thrives on consistency and scale. Load the material, run the program, and let it work—perfect for robotics engineering operations where time and accuracy matter most.